Blog

MARL Expands CNC Routing Capacity

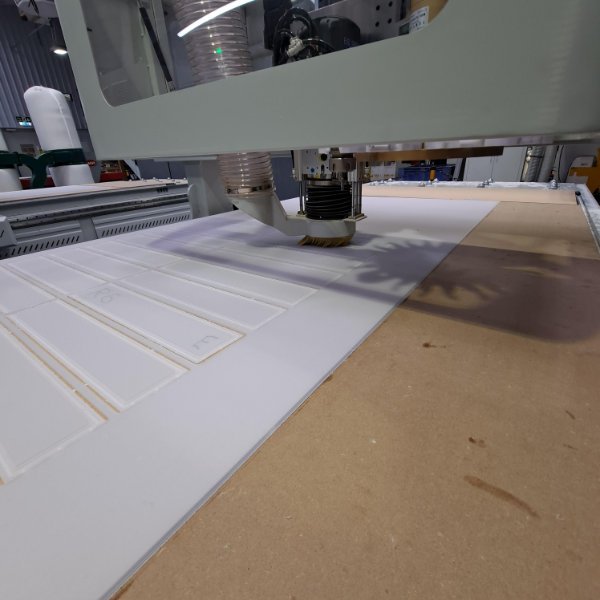

In response to the growing demands to produce in-house routed components (such as bespoke diffusers and lenses), MARL has taken delivery and installation of two new Pegasus 1530 ATC CNC Routing machines with a bed size of 1525mm x 3050mm, more than doubling our CNC Routing capacity.

Featuring an Automatic Tool Change (ATC) system, the new machines can change cutting tools within seconds, increasing efficiency and reducing downtime. Along with having two identical machines to eliminate bottlenecks and the increased speed of both machines, this has given us the agility to react quickly when called upon by our Design team for prototypes or our Production team for product components. Ultimately this provides customers with a faster turnaround time.

Image: The two machines in operation

The increased bed size and support for a wide range of materials enables greater versatility, allowing us to process larger sheet sizes and create designs on a variety of materials including plastics, metals and wood.

Enhanced precision allows for the highly accurate cutting of intricate designs, improving the quality of output and maintaining consistency between orders and the parts within a batch.

Our CNC team is delighted with the new machines, which have made their work easier, safer and more efficient.

For more information contact [email protected].